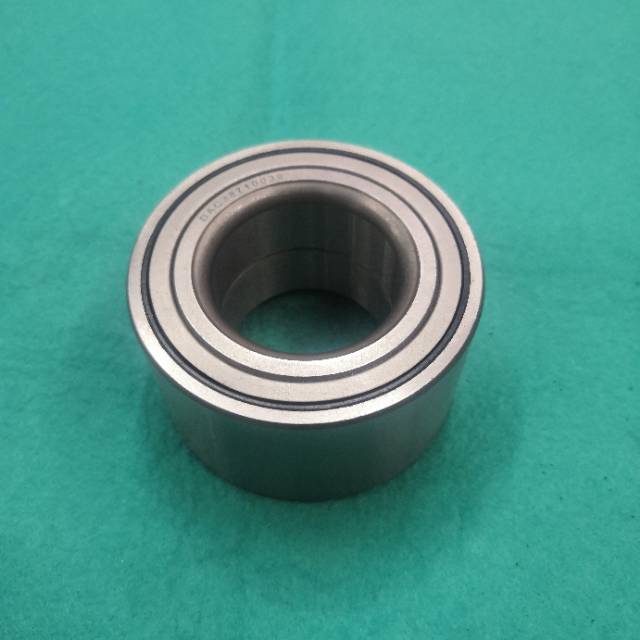

During the operation of the vehicle, the automobile bearing, as one of the core components, directly affects the stability and safety of the vehicle. This article will take the automobile bearing (outer diameter 71mm, inner diameter 38mm, height 39mm) as an example, take you to understand the importance of this part and its selection and maintenance methods.

Automotive bearing basics: uncovering the secrets behind size

Automotive bearings are precision mechanical parts used to support rotating shafts and reduce friction. Its main parameters include outer diameter, inner diameter and height, which determine the application scenario and performance of the bearing.

Specifically, the outer diameter refers to the size of the outer diameter of the bearing; the inner diameter refers to the diameter of the central hole, which is usually used to match the drive shaft; and the height reflects the overall thickness of the bearing. Each parameter has strict tolerance requirements, so it must be accurately selected according to the actual situation.

the specific meaning and importance of outer diameter 71mm, inner diameter 38mm and height 39mm

This type of automotive bearing has a specific proportional relationship, which can meet the needs of small and medium-sized vehicles. Example:

- -The outer diameter of 71mm provides enough strength to carry the load;

- -The inner diameter of 38mm is suitable for most standard drive shaft connections;

- -The height of 39mm ensures good space utilization while taking into account stability.

In addition, these bearings also have high speed capability and wear resistance characteristics, and can still maintain excellent performance under long-term use.

Which models are suitable for? A comprehensive analysis of the scope of application and typical use

This type of automotive bearing is widely used in passenger cars, light trucks and other mechanical equipment that requires low noise and high precision operation. This is particularly suitable for the joint bearing position in the steering knuckle region of the front wheel drive system or in the rear axle suspension assembly.

not only that, due to the use of high-quality steel manufacturing and heat treatment process to strengthen the hardness, even in the face of bad road conditions can also show reliable durability.

How to select high-quality automotive bearings? Key indicators are all in one net

in order to ensure the purchase of qualified products, please pay attention to the following aspects:

first check whether there is a regular manufacturer certification mark, and verify whether the relevant technical parameters are accurate. Secondly, observe the surface finish and flatness to avoid obvious defects or rust. Finally, the actual size deviation can be measured with the help of special instruments to confirm the quality level.

Maintenance Guide: The Secret Weapon to Extend the Life of Automotive Bearings

The correct maintenance method can help extend the service life of the bearing. Regularly clean up dirt substances to prevent impurities from invading and causing abnormal wear; timely supplement grease to reduce the friction coefficient between the contact surfaces to slow down the aging speed; in case of serious damage, replace new parts in time to avoid causing greater failure problems.

Case sharing: customer experience summary of successful installation and use

Many car owners reported that after the correct selection of the corresponding specifications of the car bearings, not only the comfort of the driving process is improved, but also the maintenance frequency and cost are significantly reduced. A driver who has been engaged in the logistics and transportation industry for a long time said, "since changing this high-performance bearing, the car has run more steadily and faster!"

This fully reflects the scientific and reasonable choice for the overall benefit of the important significance.