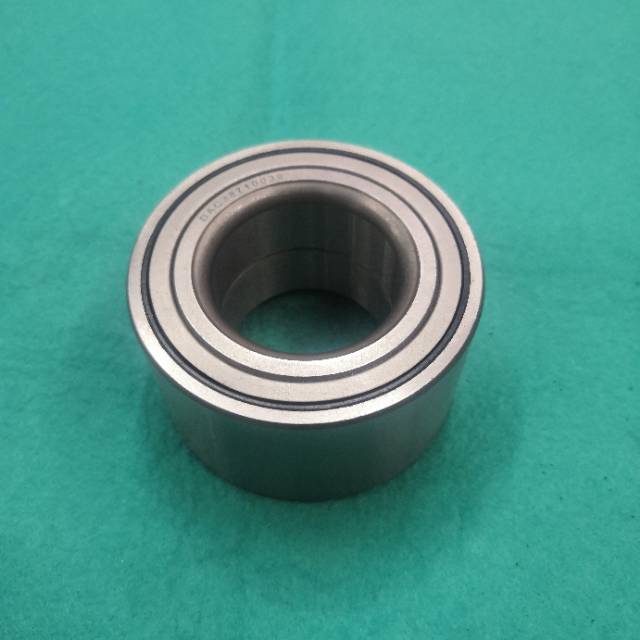

In the world of mechanical engineering, every component plays a vital role. Today we are going to focus on a seemingly inconspicuous but extremely critical component-automotive bearings. Especially for products that require precise dimensions, such as professional-grade automotive bearings with an outer diameter of 71mm, an inner diameter of 38mm, and a height of 39mm, its importance cannot be ignored.

Choosing the right size of automotive bearings is not only to meet the basic functional requirements, but also to ensure the efficient operation and long-term stable performance of the entire system. If the bearing is too large or too small, it may cause unstable operation of the equipment or even damage other parts. Therefore, in the procurement process must carefully check the specifications and parameters, and select brand products that meet international standards certification.

This specific model (outer diameter 71mm × inner diameter 38mm × height 39mm) is made of top-grade steel and processed through advanced heat treatment processes, so that it has excellent wear resistance and fatigue resistance. At the same time, the surface finish is extremely high, which effectively reduces the friction coefficient, thereby improving work efficiency and reducing energy consumption.

These bearings are used in a wide variety of industrial applications, including but not limited to the support of steering systems, brakes, and other high-speed rotating components in the automotive industry. Due to their excellent load-bearing capacity and durable life, they are very suitable for working environments that withstand heavy loads and frequent starts and stops.

Compared with many ordinary quality or counterfeit products on the market, this one we recommend to our customers has significant advantages. First of all, from the beginning of the selection of raw materials, we will strictly control the quality of each production link. Secondly, the assembly accuracy reaches micron level, which ensures that the perfect fit after assembly will not loosen. Finally, a special coating protective layer is added to resist the erosion effect of external harsh weather conditions.

For a longer return on your investment, please follow some simple maintenance suggestions: regularly clean up dust particles to avoid unnecessary wear damage caused by blocking the rolling track area; timely apply the right amount of lubricating oil to maintain smooth rotation and prevent rust Corrosion problems occur. These methods can not only greatly slow down the aging rate but also help to find potential failures and repair them in time to avoid greater losses.

Many users have successfully used this series of bearings in their engineering projects, and have given high evaluation feedback, which shows that they can maintain good performance and consistently provide high-quality service support under extreme temperature environments or continuous high-pressure operating conditions. I believe that with such excellent technical strength and considerate after-sales guarantee system, every customer will feel that it is worth the money.