Required for car maintenance |

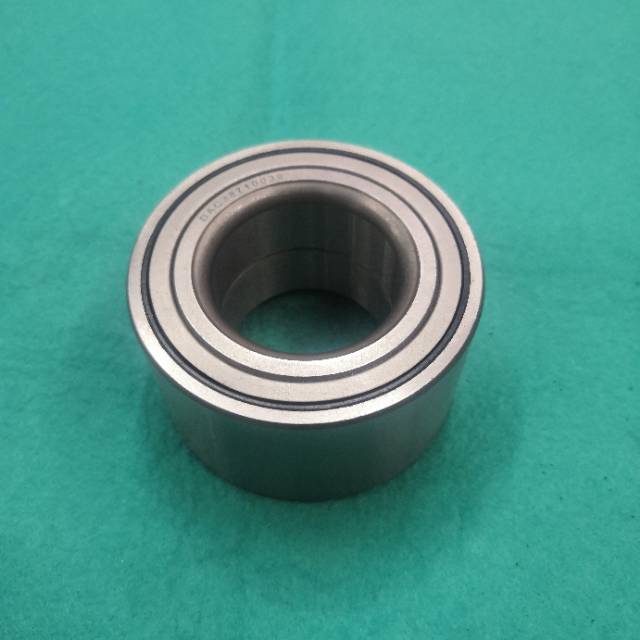

For every car owner and maintenance technician, choosing the right parts is one of the key steps to ensure the normal operation of the vehicle. Today we will focus on a widely used high-precision automotive bearing with an outer diameter of 71mm, an inner diameter of 38mm and a height of 39mm, in-depth understanding of its core parameters and the significance behind it.

This series of bearings is highly regarded, in large part due to its precise geometric design. These numbers are not just a simple set of data, they represent the precise idea of engineering. For example, when the bearing is mounted to a hub or other transmission component, an accurate ratio of the inner to outer diameter can significantly reduce the coefficient of friction and help spread the load pressure to achieve a longer service cycle.

Of course, in addition to size, material and manufacturing process are also important factors in determining bearing life. High-quality steel combined with advanced heat treatment technology, so that this type of bearing has excellent wear resistance and fatigue strength. In addition, the surface finish and the degree of smoothness can not be ignored; only after fine grinding processing of the finished product can really achieve the expected performance standards.

However, having a good quality product is only the basis for the success of the first step, and the correct assembly method is also indispensable. Please be sure to read the relevant manual carefully or consult a professional for guidance before carrying out the actual operation. In general, it is necessary to pay attention to the clean working environment to prevent foreign matter from entering the internal space and causing damage. In addition, it is necessary to ensure that the torque of the fastening screws is uniform and appropriate to avoid early failure due to excessive compression.

At the same time, there are still many questions around this type of bearing waiting to be answered. For example, one might ask, "What if I find that the existing system is aging and damaged?" In such a case, replacing the entire component may be a more economical option rather than trying to repair the local damage. Another common problem is the requirement of storage conditions-it is recommended to place unopened new pieces in a dry and cool place away from the threat of chemical attack so that they can be recalled at any time.

The last but not the least important link is the importance of daily maintenance measures to remind. Regularly checking whether the lubricating oil level is sufficient and replenishing the missing amount in time can help delay the loss rate caused by direct contact between metals. At the same time, attention should also be paid to whether there is abnormal noise as an early warning signal of potential failure.

To sum up, through the above detailed introduction, I believe readers have a more comprehensive and profound understanding of automotive bearings under this specific specification. Whether you are a novice driver or an experienced mechanic, mastering this knowledge will contribute to your future driving safety escort.