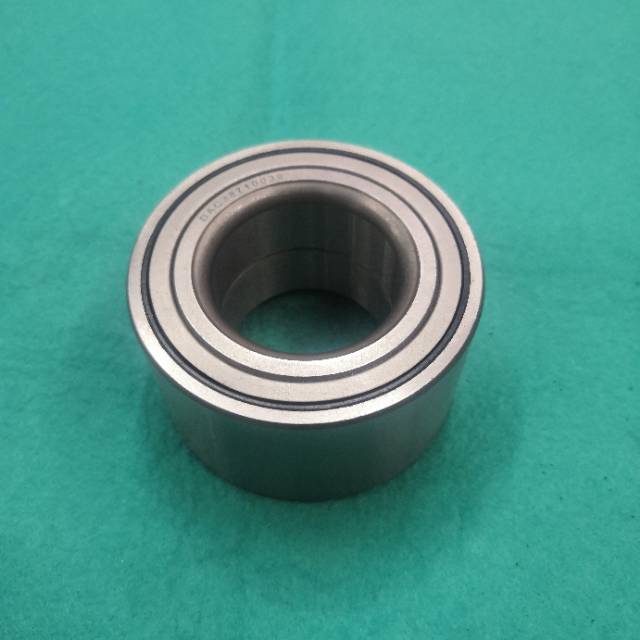

In the automotive industry, the accuracy and reliability of each part directly affect the safety and stability of the vehicle. As one of the core components of automotive bearings is particularly important. Today we will focus on a high-performance automotive bearing-a product with an outer diameter of 71mm, an inner diameter of 38mm, and a height of 39mm, and discuss its uniqueness and its application scenarios.

Dimensional accuracy is one of the important indicators to measure the quality of automotive bearings. Even minor deviations can cause the equipment to run poorly or even damage other related components. Therefore, the error range must be strictly controlled in the production process to ensure the excellent performance of the final product. This bearing through precision machining process to achieve extremely high tolerance standards, so as to provide users with a more smooth operation experience.

An in-depth study of this bearing with specific parameters (71 x 38 x 39mm) reveals many significant advantages. First of all, it is suitable for various types of passenger vehicles and commercial vehicles in the steering system and suspension devices and other fields; secondly, due to the selection of high quality steel and a special heat treatment program to make the hardness and toughness reach the ideal balance state, so it can work in extreme conditions for a long time without being easy to wear or deformation.

the whole process from the selection of raw materials to the delivery of finished products needs to go through layers of checks to achieve a real top-level product. For example, this series of bearings are forged with imported high-grade alloy steel raw materials, and a series of steps such as assembly and debugging are completed in combination with advanced technical means on automatic production lines, and then they are tested one by one before they are put into the market and sales link.

actual users often have high expectations for such high-end configurations, so let's take a look at some feedback from real users! Many car owners have reported that since the replacement of this new model, they have obviously felt that the noise has been reduced a lot and the control has become easier and easier. Some maintenance technicians also mentioned that the installation is simple and fast and the maintenance cost is lower in the later period. These characteristics are very satisfactory.

in order to further extend the life of the car bearing you purchased, there are some simple and effective maintenance tips for reference: regularly check the lubrication condition and supplement the corresponding grease when necessary to reduce friction loss; Avoid overload operation to avoid unnecessary pressure damage; Clean up external dust particles in time to prevent foreign matter intrusion from causing failure problems, etc.

finally, before we prepare to purchase new parts to replace the old damaged parts, we must clarify our own needs and then carefully screen the advantages and disadvantages of multiple options to make wise decisions. In addition to paying attention to the price factor, it is also necessary to comprehensively consider the brand reputation, after-sales service and other information, so as to truly make a good comparison between the three companies to buy satisfactory good things.