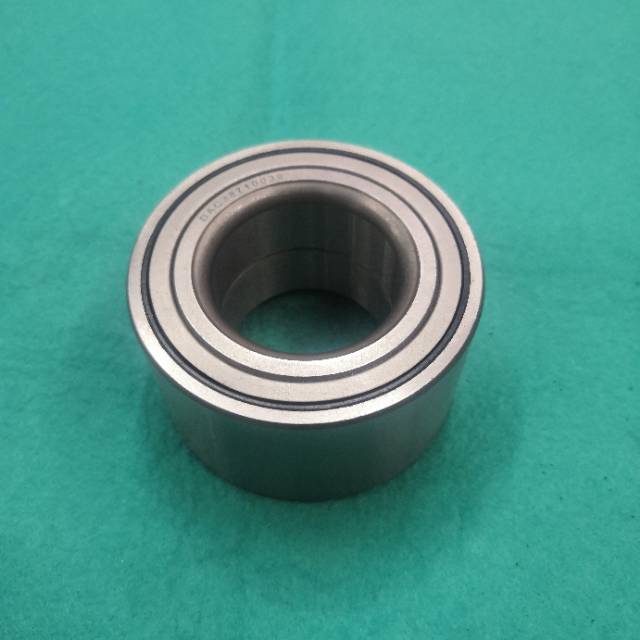

In the context of the rapid development of the modern automobile industry, the quality of every screw and every component will directly affect the performance of the vehicle and driving safety. automobile bearing outer diameter 71 × inner diameter 38 × height 39 is a professional mechanical component specially designed for high-strength working environment. with its accurate size matching and excellent compressive performance, it has gradually become one of the core spare parts selected by many repair workshops and host manufacturers.

Reveal the hard core strength of automobile bearing: technical code of outer diameter 71 × inner diameter 38 × height 39

this type of bearing adopts standard size setting with strong versatility, namely outer diameter 71mm, inner diameter 38mm, total height 39mm , which perfectly fits the installation hole configuration of most passenger car hub shafting. Both cars and light trucks can realize compatible docking without modification, greatly improving the replacement efficiency.

Compared with regular products on the market, the internal roller arrangement of this bearing has been structurally improved, so that the load force is more uniform, and it can still be maintained under frequent start-stop or bumpy road driving conditions. Stable rotation without offset and jitter.

More importantly, its sealing protection level has reached IP67 level, which can work normally in wading potholes, resist dust intrusion, and ensure smooth and worry-free long-term operation.

Double Addition of Material and Process: Exploring the Manufacturing Mysteries Behind High Performance

Quality material is one of the key factors that determine the life of a bearing. To this end, we select special alloy steel with carbon content up to 0.9% as the base material, and after triple quenching treatment, the hardness value can reach HRc58 ~ 62 range, which significantly enhances the ability to resist friction loss.

The entire production process adopts CNC grinding equipment for precision machining to ensure that the inner and outer circumference errors are less than ± 0.005mm, which fully meets the requirements of ISO/ABEC P0 tolerance specifications. Even the subtleties strive for extreme precision, thereby reducing the probability of vibration and abnormal noise.

In addition, a layer of graphite composite lubricating film is specially coated, which can maintain good sliding characteristics even when encountering extreme temperature difference changes, and greatly delay the time node of early aging problems.

Practical application Full perspective: How did the star players in the auto repair workshop perform?

during the field test of more than ten large chain maintenance stations all over the country, the technicians unanimously evaluated that the bearing assembly is extremely convenient, and the lock nut fixing device can be put in place at one time without repeatedly adjusting the fit clearance, thus greatly saving the labor cost.

there are many experienced old masters who said: "in the past, when changing other brands, we often encountered situations where we couldn't get in or could barely get in but couldn't rotate freely. however, this batch of goods never let us down." Field measured data show that there is no obvious sign of looseness after continuous use for more than 6,000 kilometers.

Follow-up follow-up visits showed that car owners generally reported that the steering feel was smoother after the replacement, the consistency of the brake pedal feedback was strengthened, and even the tire noise was reduced, and the driving comfort was substantially improved.

Industry Purchasing Guide: Why it's a hot item in the supply chain

At present, hundreds of parts wholesalers across the country have established stable supply channels, and the average monthly order growth rate has remained at double-digit levels. Especially in the peak period before and after the holidays, there is often a rush to buy out, showing strong market demand support.

what is more noteworthy is that the original supporting production lines of several well-known commercial vehicle brands in China have successively introduced this type of bearing to participate in the new car assembly process, which means that its quality has been endorsed by authoritative certification.

after considering the three core elements of unit price, life cycle and after-sales repair rate, it is concluded that although the initial investment is slightly higher than the competition by about 5%-8%, the cost-effective advantage is very prominent in the long run, which is very suitable for batch centralized procurement deployment.

Prospect of future development trend: whether high-precision bearings are rewriting the industrial pattern

With the wave of electrification sweeping the global automotive industry, major car companies have accelerated the launch of a new generation of new energy platform architecture. In this situation, mature solutions for traditional fuel vehicles are also beginning to face a window of opportunity to be re-examined.

it is worth looking forward to, based on the existing physical basis of superposition of wireless sensing module will become one of the possible development directions, then through the cloud synchronous collection of real-time operation data stream to implement preventive maintenance reminder service, further expand the intelligent operation and maintenance ecosystem territory.

At the same time, local manufacturers are also actively catching up with advanced foreign companies, striving to break the long-term monopoly of discourse power dominated by Japan, Germany and the United States. I believe that in the near future, "Made in China" will surely win higher praise and prestige on the world stage.