It was a rainy Tuesday evening when Sarah’s SUV groaned to a halt on the shoulder of a winding mountain road. No warning lights, no dramatic smoke—just a low growl that had been creeping into her drives for weeks, now culminating in a shuddering resistance from the front wheel. The culprit? A failing wheel bearing. Something so small it could fit in the palm of her hand had quietly compromised her safety, comfort, and confidence behind the wheel. This is the hidden truth of automotive engineering: sometimes, the smallest components carry the heaviest responsibilities.

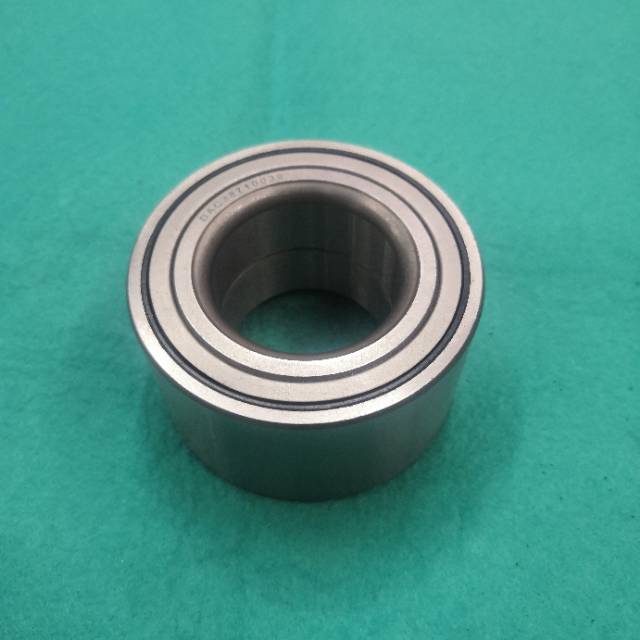

Beneath every smooth turn, every mile logged on the open highway, lies a network of precision parts working in silent harmony. And at the heart of many suspension and drivetrain systems sits a seemingly modest ring of steel—the automobile bearing. Our latest innovation, meticulously crafted with an outer diameter of 71mm, inner diameter of 38mm, and a height of 39mm, isn’t just another replacement part. It’s a recalibration of what reliability feels like.

71×38×39: The Silent Language of Perfect Fit

Think of these three numbers as the skeleton of compatibility—OD 71mm, ID 38mm, Height 39mm. They’re not arbitrary; they’re the exacting blueprint that determines whether a bearing integrates seamlessly or fights against its housing. Too wide, and the seal binds under pressure. Too narrow, and lateral play introduces dangerous vibration. Just like wearing shoes two sizes too small can exhaust even the strongest runner, a misaligned bearing forces the entire drivetrain to compensate. Every rotation becomes a battle. But with our precisely dimensioned design, installation is intuitive, seating is secure, and load distribution remains optimal—even under stress.

Forged in Fire, Refined by Precision

This bearing doesn’t begin life as a blank slab of metal. It starts in the crucible—high-carbon chromium steel chosen for its resilience and fatigue resistance. From there, it undergoes multiple stages of heat treatment: quenching to lock in hardness, tempering to restore toughness, and cryogenic stabilization to eliminate internal stresses. Then comes the dance of CNC grinding, where tolerances are measured in microns. Each raceway is polished to a mirror finish, reducing friction to near-zero levels. Finally, every unit spins through dynamic balance testing—simulating years of real-world abuse—to ensure flawless rotation at any speed.

The Quiet Strength Behind Extreme Conditions

You won’t hear this bearing working—because it’s designed to be silent even when pushed to extremes. Imagine navigating a sharp downhill switchback with a full trailer in tow. Lateral forces press in, heat builds up, and rotational stress peaks. Or picture sustained braking on city streets during rush hour, where constant deceleration turns kinetic energy into thermal load. In these moments, inferior bearings whine, chatter, or seize. Ours maintains composure. Advanced double-seal technology keeps contaminants out while retaining high-temperature grease, ensuring consistent lubrication across thousands of miles.

Replacement Should Never Mean Compromise

Many drivers assume “replacement” means returning to factory condition. But here’s the reality: some OEM-spec parts were never built for longevity. We’ve seen customers return after just three months, frustrated by renewed noise and vibration. One fleet manager reported replacing cheap bearings four times in 18 months—until he switched to ours. Two years later, those same units are still running strong. That’s the cost of cutting corners: short-term savings, long-term headaches—and potential damage to hubs, axles, and even control arms. Our bearing isn’t just durable; it’s protective.

A Universal Fix for Real-World Challenges

While engineered to meet exact dimensional standards, this bearing transcends simple model-specific applications. It thrives in diverse scenarios: restoring vintage sedans where original parts are obsolete, upgrading off-road SUVs that demand rugged reliability, or supporting commercial vans logging 50,000+ miles annually. Whether you're rebuilding a classic project car or managing a delivery fleet, this component serves as a universal anchor of dependability—a quiet hero in the machinery of motion.

Engineered Beyond Necessity

We’ll admit something: we test our bearings beyond their rated limits. In our lab, we deliberately overload them—spinning faster, pressing harder, heating longer—until failure occurs. Why? Because understanding the breaking point allows us to set our operating range far below it. Most manufacturers aim for adequacy. We aim for over-engineering with purpose. When our team says “this will last,” we mean it has already survived more than your vehicle will ever ask of it.

Hear What Silence Sounds Like

After installation, drivers often describe the same experience: a newfound clarity in steering response, a tighter connection between road and cockpit. The hum that used to rise at 50 mph vanishes. Bumps feel controlled, not jarring. At highway speeds, the cabin breathes easier. These aren’t placebo effects—they’re measurable reductions in vibration and rolling resistance. You don’t notice the bearing. And that’s exactly how you know it’s doing its job perfectly.

Driving Further, Sustaining Longer

In an age where sustainability matters, true eco-conscious driving isn’t just about electric motors—it’s about extending the life of existing machines. Fewer replacements mean less waste, lower manufacturing emissions, and reduced resource consumption. By choosing a bearing built to outlast expectations, you’re not just investing in performance. You’re committing to fewer repairs, less downtime, and a smaller environmental footprint. The future of driving isn’t always about going faster. Sometimes, it’s about lasting longer—quietly, reliably, mile after mile.