驾驭精密:当尺寸遇见卓越——71mm x 38mm x 39mm轴承背后的工程美学

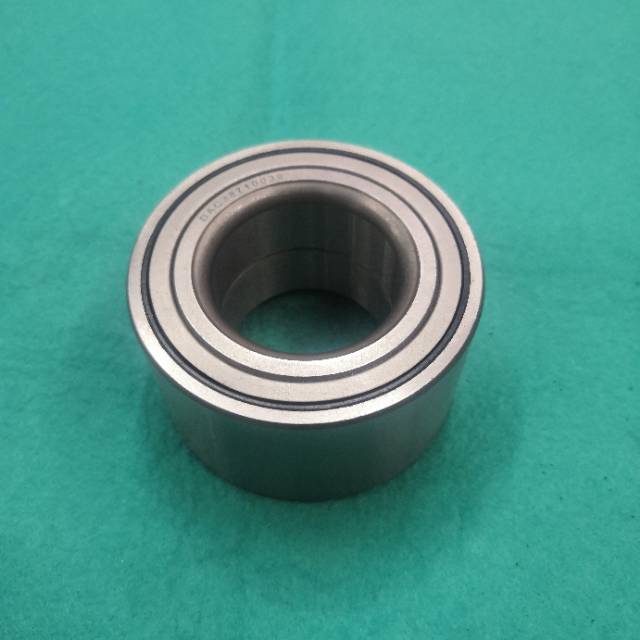

In the symphony of automotive motion, every component plays its part — but few do so with the quiet dignity of the humble bearing. Nestled within wheel hubs, transmissions, or auxiliary systems, this unassuming ring of precision steel ensures your vehicle moves forward smoothly, efficiently, and reliably. At the heart of many modern drivetrains lies a critical yet often overlooked hero: the 71mm x 38mm x 39mm automobile bearing. More than just a mechanical spacer, it's an engineered masterpiece designed to handle stress, speed, and time.

不只是金属圈:解读一个被忽视的汽车“心脏”角色

From the moment you turn the key, forces begin to cascade through your car’s moving parts. The engine fires, gears engage, wheels spin — and at countless pivot points, bearings absorb radial and axial loads while minimizing friction. This particular bearing, measuring 71 millimeters in outer diameter, 38 in inner diameter, and 39 millimeters in height, serves as a crucial interface between rotating shafts and static housings. It doesn’t generate power, but without it, that power could never be delivered effectively to the road.

三围决定使命:为何71-38-39是性能的黄金比例?

The dimensions of a bearing are never arbitrary. Each measurement is the result of meticulous engineering trade-offs involving space constraints, load requirements, and rotational dynamics. The 71mm outer diameter provides robust structural integrity, allowing it to fit securely into standard housing units across a range of vehicles. With a 38mm bore, it accommodates common axle and shaft sizes found in mid-sized sedans, SUVs, and light commercial vehicles. Its 39mm thickness strikes an ideal balance — sufficient to support dual-row ball configurations for enhanced load capacity, without adding unnecessary bulk. This dimensional harmony makes it a versatile choice for OEM replacements and aftermarket upgrades alike.

在高温与高压之间跳舞:耐久性是如何炼成的?

Imagine enduring thousands of revolutions per minute, year after year, under extreme thermal cycling and mechanical vibration. Bearings operate in one of the harshest environments inside a vehicle. To survive these conditions, this 71x38x39 bearing is crafted from high-purity chromium alloy steel, known for its exceptional hardness, fatigue resistance, and dimensional stability. Through a precisely controlled heat treatment process — including quenching and tempering — the microstructure of the metal is optimized to resist cracking and surface spalling. Sealed variants further protect against dust, moisture, and contaminants, ensuring consistent performance even in demanding climates.

顺滑如丝的秘密:精度如何定义驾驶质感

Smooth driving isn’t just about suspension tuning or tire quality — it begins with internal mechanical refinement. A mere micron of deviation in raceway geometry can lead to increased noise, vibration, and harshness (NVH). That’s why this bearing undergoes ultra-precision grinding and lapping processes, achieving ABEC-3 or higher tolerances. Dynamic balancing ensures minimal runout during rotation, translating directly into quieter operation and reduced wear on adjacent components. Drivers may not notice a perfectly functioning bearing — but they’ll certainly feel the difference when it’s missing.

跨界适配:从SUV到轻型商用车的通用解决方案

Versatility is built into its design. Whether supporting rear wheel hubs in all-wheel-drive SUVs, enabling smooth compressor function in climate control systems, or stabilizing driveshaft joints in delivery vans, this bearing proves its adaptability. Its standardized dimensions align with numerous manufacturer specifications, making it a trusted go-to for mechanics and fleet maintenance teams. Even in hybrid and electric platforms, where torque delivery differs significantly from traditional engines, such precision components remain indispensable for managing high-torque, low-RPM operations.

无声守护者:可靠性背后的测试哲学

Quality isn’t assumed — it’s proven. Before leaving the factory, each batch of these bearings undergoes rigorous life cycle testing. Simulated overloads, accelerated aging, temperature swings from -40°C to +150°C, and continuous rotation tests mimic five years of real-world use in just weeks. Advanced metrology tools verify dimensional consistency, while non-destructive inspections detect subsurface flaws invisible to the naked eye. Every unit carries traceable lot codes, ensuring full accountability and recall readiness if ever needed.

未来在路上:高性能轴承如何推动出行进化

As vehicles evolve toward electrification and autonomy, the demand for silent, reliable, and maintenance-free components grows. In electric drivetrains, where NVH standards are stricter due to lack of engine masking noise, bearings like this become even more critical. Future iterations may integrate smart sensors for predictive maintenance, monitoring wear in real time. But today’s 71x38x39 bearing already lays the foundation — combining durability, precision, and adaptability to meet both current needs and tomorrow’s challenges.

选对零件,就是选择安心旅程

Replacing a worn bearing isn't just routine maintenance — it's an investment in safety, comfort, and longevity. Choosing a premium-grade replacement ensures compatibility, performance, and peace of mind. When you install a bearing engineered to original equipment specifications, you're not just fixing a part — you're restoring confidence in every mile ahead. Because true performance isn't always visible. Sometimes, it's hidden in a 71mm ring of precision steel, turning silently beneath your feet.