Precision at Its Core: The 71mm Outer Diameter Automobile Bearing Powering Modern Vehicles

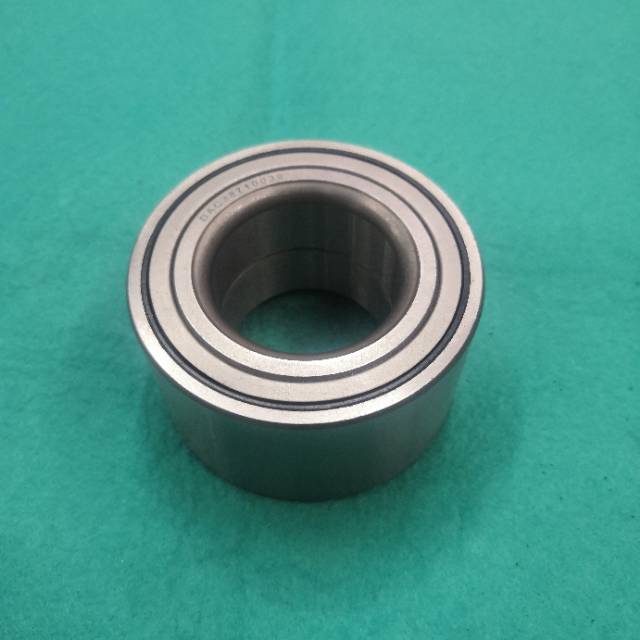

Discover how the 71mm outer diameter, 38mm inner diameter, and 39mm height bearing plays a vital role in enhancing vehicle performance and durability.

The Engineering Behind the Numbers

The dimensions of an automobile bearing are not arbitrary. The 71mm outer diameter, 38mm inner diameter, and 39mm height were carefully selected to meet a wide range of mechanical requirements in modern vehicles. These measurements strike a balance between structural integrity and spatial efficiency, making them ideal for various automotive applications.

Each millimeter contributes to how the bearing interacts with the forces it must withstand. The outer diameter ensures a stable fit within the housing, while the inner diameter accommodates the necessary shaft size without compromising rotational efficiency. The 39mm height provides enough structural depth to support dynamic loads, especially under high-speed conditions.

This standardization also allows for interchangeability across different vehicle platforms, simplifying both manufacturing and repair processes. As a result, this particular bearing size has gained popularity among automotive engineers and technicians alike.

From Design to Reality: The Making of a High-Performance Bearing

The journey of this automobile bearing begins in the design lab, where engineers simulate real-world stress conditions to ensure optimal performance. Advanced CAD modeling and finite element analysis help determine the ideal geometry, material composition, and internal clearance tolerances.

Manufacturing follows with precision machining and rigorous quality control. Each bearing undergoes multiple stages, including forging, grinding, and heat treatment, to achieve the desired hardness and fatigue resistance. The surfaces are often coated with protective layers to resist corrosion and wear.

Materials such as high-grade chrome steel or stainless steel are selected for their durability and ability to withstand extreme temperatures. This meticulous attention to detail during production ensures that each 71x38x39 bearing delivers consistent performance over its operational life.

Where It Works: Integration into Critical Vehicle Components

One of the most common applications of this bearing is within the wheel hub assembly. It supports the vehicle's weight while allowing smooth rotation of the wheels. Whether in front or rear axles, this bearing ensures minimal friction and maximum stability.

Beyond the wheels, it also plays a key role in the transmission and differential systems. Here, it helps maintain gear alignment and reduces mechanical wear, contributing to longer component life and smoother shifting. The bearing's compact yet robust design makes it compatible with a wide array of engine types and vehicle models, from compact sedans to high-performance sports cars.

Its versatility extends to compatibility with both internal combustion engines and hybrid powertrains, positioning it as a crucial component in the evolving automotive landscape.

Whisper-Quiet Efficiency: The Comfort Behind the Performance

Modern drivers expect not only performance but also comfort. This bearing is designed with noise reduction in mind. Through optimized internal geometry and high-precision ball and raceway surfaces, it minimizes operational noise, ensuring a quieter ride even at high speeds.

Lubrication channels are strategically designed to maintain consistent oil flow, reducing heat buildup and friction. This leads to lower energy loss and improved fuel efficiency. In comparative tests, vehicles equipped with this type of bearing showed a noticeable reduction in drag and noise levels compared to older bearing designs.

These improvements might not be immediately visible, but they contribute significantly to overall driving satisfaction and long-term vehicle reliability.

Enduring the Elements: Performance in Harsh Conditions

Automotive bearings must endure more than just mechanical stress. Exposure to moisture, dust, and temperature extremes can quickly degrade performance if not properly addressed. The 71x38x39 bearing is engineered with sealed or shielded designs that prevent contaminants from entering critical areas.

Anti-corrosion treatments and high-quality sealing materials extend the bearing's life, even in demanding environments. Field tests have demonstrated its ability to maintain smooth operation under conditions ranging from sub-zero winters to desert heat.

With proper installation and maintenance, these bearings can last tens of thousands of kilometers. Recommended service intervals depend on driving habits and environmental conditions, but many users report minimal issues even after extended use without replacement.

More Than a Component: Enhancing the Driving Experience

While often overlooked, the right bearing can have a measurable impact on overall vehicle performance. By reducing friction and improving rotational efficiency, it contributes to better fuel economy and lower emissions. This aligns with the growing emphasis on sustainability and eco-friendly driving.

In the era of smart and electric vehicles, this bearing also demonstrates impressive adaptability. Its design supports the integration of sensor technology, allowing for real-time monitoring of wheel speed and condition. This compatibility makes it a forward-thinking choice for next-generation automotive systems.

As electric vehicles gain popularity, the demand for high-efficiency, low-noise bearings continues to rise. The 71x38x39 dimension is well-positioned to meet these evolving needs, making it a promising candidate for widespread adoption in future automotive platforms.

Voices from the Field: Trusted by Professionals and Manufacturers

Automotive technicians appreciate the ease of installation and the consistency of performance across multiple units. Many describe it as a "reliable workhorse" in their daily repairs. The fact that it often comes pre-lubricated and sealed further reduces maintenance time and complexity.

Vehicle manufacturers, too, recognize its value. It is frequently chosen as original equipment due to its proven track record and compatibility with existing systems. High customer satisfaction and repeat purchases are a testament to its reliability and performance in real-world conditions.

Whether in new builds or aftermarket replacements, this bearing has earned a reputation for being a dependable, high-quality solution that meets both mechanical and economic demands.

Looking Ahead: A Potential Industry Benchmark

As automotive technology continues to evolve, so too do the components that make vehicles run smoothly. The 71x38x39 bearing has already demonstrated its versatility across traditional and emerging vehicle types. With the rise of autonomous driving and electric mobility, bearings will need to support new types of loads and integrate with digital monitoring systems.

Manufacturers are already exploring enhancements such as ceramic hybrid balls, improved sealing mechanisms, and embedded sensors for predictive maintenance. These innovations could further solidify the 71x38x39 bearing's place as a standard in the industry.

If current trends continue, this dimension may well become a new benchmark for automotive bearings, setting the standard for performance, durability, and adaptability in the vehicles of tomorrow.