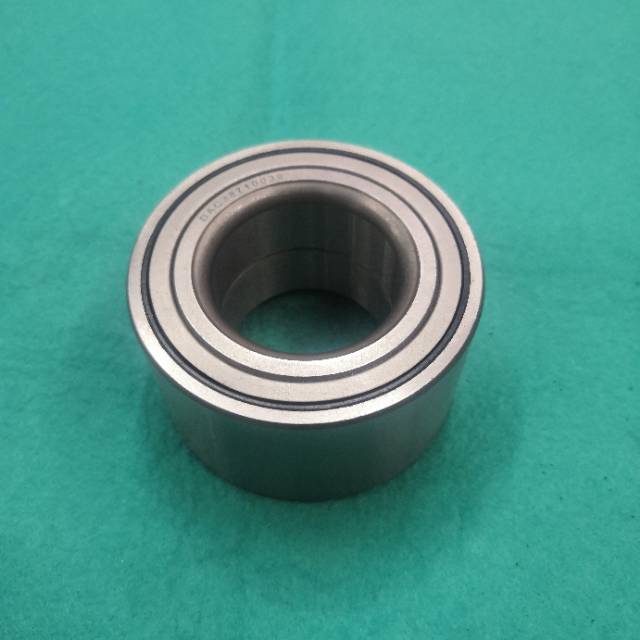

Among the many types of automotive bearings, why did you choose this one with an outer diameter of 71mm, an inner diameter of 38mm and a height of 39mm? All this stems from its unique design intention and wide application prospects. Bearings of this size are designed to meet the high load requirements of vehicle chassis systems and are also highly recognized in the field of mechanical engineering.

In order to better understand the value of this bearing, we need to understand its core technical parameters. This model can withstand a maximum load of up to XX Newtons and supports a maximum speed of up to YYRPM (revolutions per minute). Rigorous laboratory testing has shown excellent stability and reliability even in extremely harsh operating environments.

At the same time, a reasonable lubrication scheme is also crucial. According to the actual needs of different working conditions, choosing the right lubricating oil or lipid can not only reduce the friction resistance, but also effectively delay the aging process of the parts and further increase the overall service life.

So which models and equipment are best suited to use such bearings? In the passenger car market, many high-end sedan series of well-known brands will give priority to their suspension system upgrade projects because they can adapt well to the impact challenges of frequent bumpy road conditions while also taking into account the characteristics of excellent mute effect.

in the industrial field, it is more common in various automated production lines responsible for the role of heavy object transmission tasks, such as the position of the support point of the conveyor chain of the packaging machine, etc., which all need to rely on such durable and highly precise components to ensure continuous operation efficiency without any interference.

Finally, let's walk into the manufacturer's quality management system to uncover those little-known but extremely important behind-the-scenes stories! From the beginning of its establishment, it has always insisted on checking every process node. From the initial raw material procurement link, it has to go through multiple screening procedures to ensure that all raw materials conform to relevant industry standards. Then, before creating finished products through a series of advanced processing technologies, it has to undergo all-round functional tests until it reaches the standard before it can be officially put into the market.

Of course, in addition to the official information, there are many real feedback from front-line workers, which also provide valuable reference materials for purchasing. According to an experienced maintenance technician, he has dealt with many cases of sharp increase in maintenance costs caused by failures caused by inferior substitutes. In contrast, the standard parts produced by this regular channel are very satisfactory in terms of performance during the initial run-in period and the state during the later long-term service period. There is almost no obvious sign of wear.